Sorry. We did not find anything.

FUSO.

A PART OF DAIMLER TRUCK AG.

The FUSO brand is a fundamental part of Daimler Truck AG and, with nine decades of experience as an international truck and bus manufacturer, is known far beyond Japan. Commercial vehicles with the three characteristic diamonds on the radiator grille account for over a third of the total sales volume of Daimler Truck AG.

FUSO.

A SPARKLING IDEA.

In 1932, Mitsubishi Heavy Industries named one of its heavy commercial vehicles, a bus with the model designation B46, “Fuso” for the first time. The term, which is associated with honour and tradition, is traced back to the ancient Chinese word Fusang, which according to tradition refers to a sacred tree of eternal life that grows on an island, where the sun rises in the east. At the same time, Fusang can be found in early Japanese writings, still written in Chinese characters, as an ancient name of Japan, pronounced “Fuso” in Japanese. The FUSO brand was born.

By the way, when “Fuso” was proposed in an employee competition, the winner received three yen in prize money, the equivalent of almost 20 kg of rice at the time. But his suggestion did not only bring him luck: In the following decades, Mitsubishi Fuso always had its finger on the pulse of the times and, in line with the demand for transport during the economic boom and the incipient tourism boom, continuously came onto the market with ever new bus and truck models in various tonnages. The vehicles enjoyed great popularity in Japan and the first successful export deals with South America and later almost all over the world, made the company a permanent institution in the automotive industry.

FUSO.

A NEW ERA.

In 2000, the then Daimler-Chrysler AG laid the foundation for a strong partnership in Asia by acquiring 34% of the shares in the Japanese carmaker Mitsubishi Motors Corporation (MMC). With its extensive product portfolio of trucks and buses and its enormous presence in the Asian commercial vehicle markets, Mitsubishi FUSO was of great importance for the global growth strategy of the German automotive group.

The truck and bus division was spun off from MMC and Daimler-Chrysler became the majority shareholder of the newly created Mitsubishi FUSO Truck & Bus Company (MFTBC) with a 65% stake as early as 2004. Today, Daimler Truck AG holds just under 90% of the shares and the FUSO headquarters in Kawasaki, Japan, is not only the international competence centre for the development of light commercial vehicles within the group, but also the global development centre for new drive technologies.

MOVING MOMENTS.

THE CANTER MILESTONES.

OVER 5 MILLION ALL-ELECTRIC KILOMETRES

The FUSO eCanter, the first series-produced electric truck in worldwide customer use, has proven itself to be reliable. On a total of more than four million kilometres already, i.e. more than 100 laps around the world. FUSO celebrates this success and once again commits to alternative propulsion: the next generation of the all-electric light truck will arrive in 2023.

THE NEW CANTER IS COMING

Convincing safety features, increased comfort and an attractive, modern design – from August this year, the latest generation can be ordered through the European Mercedes-Benz dealer network. Among other things, Sideguard Assist is now available for this model series and all engines now meet the highest EU emission standards of the EURO VI (Step-E) standard.

LARGEST E-FLEET CONTRACT FOR DAIMLER TRUCKS

FUSO receives the largest electric truck fleet order in the history of Daimler Trucks. The eCanter convinced DB Schenker in the practical test. The international logistics company is reordering 36 vehicles. A strong sign for the sustainability strategy of emission-free delivery on the last mile and the pioneering partnership between the two companies.

FUSO ECANTER IN PRACTICAL USE

After the EU launch in Berlin, the eCanter, which is produced in small series, is now also on the road in the Netherlands, Great Britain and Portugal, among other countries. A total of 46 vehicles are in regular everyday use by customers with various transport applications. The experience and impressions gained from practical use are directly incorporated into the further development of the electric light-duty truck.

THE FIRST ELECTRIC TRUCK IN SERIES PRODUCTION

The FUSO eCanter is the first ever fully electric truck to go into series production. In July, the assembly line start-up will be celebrated at the plant in Tramagal, Portugal. In December, the first 14 vehicles in Europe were handed over to the four major international logistics companies DHL, DB Schenker, Rhenus and Dachser in Berlin.

THE CANTER NOW WITH FACTORY BODIES

FUSO now offers its compact light truck with platform and tipper bodies in different variants directly from the factory. Developed and tested by FUSO, they stand for maximum quality as a complete vehicle concept.

CANTER E-CELL PAVES THE WAY FOR ECANTER

After successful test drives with the first customers in Portugal, the E-CELL variant is also coming to Germany. The city of Stuttgart is integrating twelve of the locally emission-free 6-tonne trucks into its municipal operations and another vehicle is being used by parcel service provider Hermes. As the first purely electric light truck, the E-CELL model has already clocked up over 150,000 fleet test kilometres. The prototype of the current eCanter can be seen at the IAA in Hanover in the same year.

CANTER E-CELL PILOT PROJECT STARTS

The E-CELL model enters its first fleet test in Portugal as a small series. Eight customers are gathering experience with the purely battery-electric 6-tonne truck with box and platform body for one year. The test is intended to establish indications for the range and practical suitability of an electric series truck.

CANTER 4X4 AND CANTER ECOHYBRID IN EUROPE

New additions to the portfolio for the European market are a 4×4 all-wheel-drive version and an EcoHybrid version based on the TF model. With the growing variety of variants, the compact light truck increasingly meets all customer requirements.

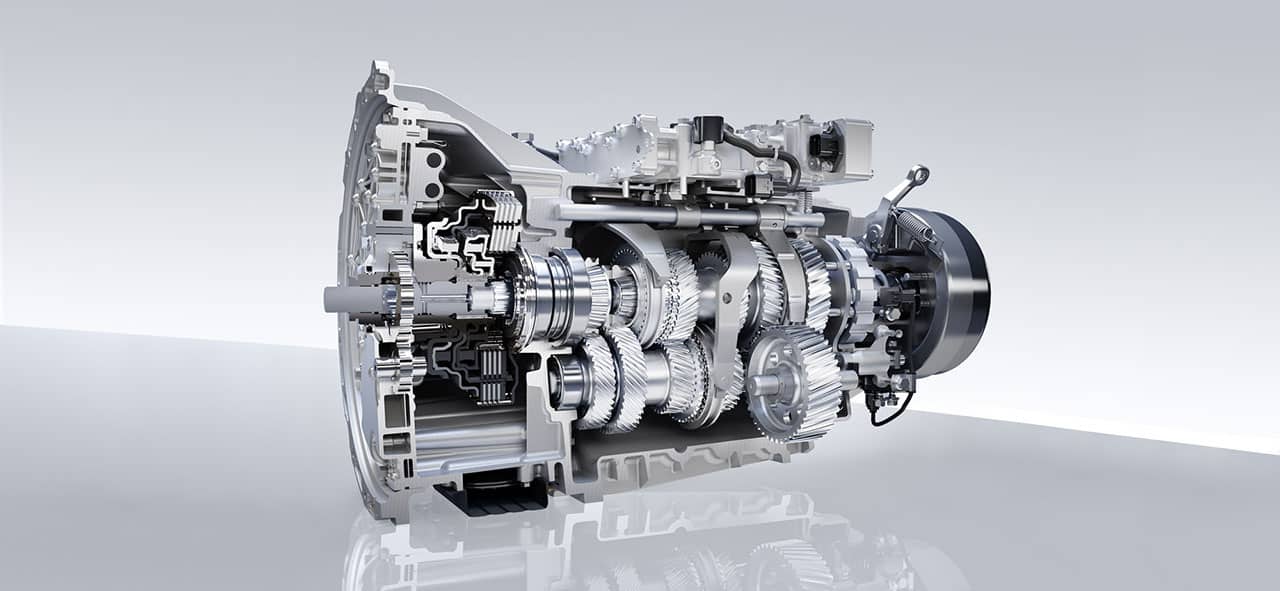

DUONIC® IS A WORLD FIRST IN THE LIGHT TRUCK SECTOR

With the TF, the next generation comes onto the market. Technology and appearance have been completely revised. One of the new features is the absolutely body-friendly frame, for which the Canter is known today. In addition, FUSO now offers it with the DUONIC® system, which was developed in-house. This makes it the first light truck in the world to have an automated dual-clutch transmission.

FUSO PRESENTS THE CANTER E-CELL

At the International Commercial Vehicle Show IAA in Hanover, FUSO is exhibiting a first concept vehicle of a purely battery-electric Canter. The Canter E-CELL is causing quite a stir, as it is technically fully functional and ready to drive.

BLUETEC® IN NEW ENGINE GENERATION FOR THE FIRST TIME

The TD receives an engine upgrade in line with the latest EEV standards and all models now meet the EURO V standard. The 175 hp variant is now equipped with BlueTec® technology developed by Daimler.

COMPLETELY NEW SERIES FOR EUROPE

With the TD model, the light truck finally arrives on the European market. It is completely redesigned and brings with it significant improvements in reliability, functionality, economy, variability and, above all, safety and comfort. The amount of space in the cabin is now as large as that of the former Sprinter. There is a new storage compartment above the windscreen and the gearstick lever is located in the dashboard for the first time. The free step-through is a first in this class.

FUSO AT MERCEDES-BENZ

Following the takeover of shares by Daimler-Chrysler, FUSO gets a central German sales organisation based in Stuttgart for the first time. Under the designation Canter TB, the FE7 and FE8 models are the brand’s first light trucks, which customers can now buy from selected Mercedes-Benz dealers.

NEW LOOK AND EURO III ENGINES

The FE7 series is the result of a model update. Extensive design changes, for example to the radiator grille and the headlights, give it a fresh look. It also gets a new generation of engines that meet the EURO III emissions standard valid in Europe. In addition, ABS is now standard in most models.

FUSO SHOWS FIRST CANTER ECOHYBRID

The presentation of a first EcoHybrid concept vehicle marks the beginning of the exceptional and pioneering research and development competence in the field of alternative drive systems even at this early stage.

THREE DECADES OF CANTER

The sixth generation of the light truck follows just in time for the 30th anniversary. The new FE5 models feature aerodynamically optimised cabs with flowing lines. With high-performance engines such as the newly developed 140 hp naturally aspirated engine with direct injection, the Canter now offers the highest displacement drive in its vehicle class.

THREE DIAMONDS AS A TRADEMARK

Under the motto “Today’s new Canter, loaded for the future”, Mitsubishi FUSO presented the FE3 and FE4 models. This next generation gets an all-round renewed and modern design concept. For the first time, the three red Mitsubishi diamonds adorn the front.

FIRST CANTER MADE IN EUROPE

The FUSO Canter for the European market is now being manufactured in Portugal. On 1 February, the first vehicle, an FE1, will roll off the production line at the central European plant in Tramagal.

CANTER CONTINUES ON THE ROAD TO SUCCESS

In the late 1970s, the market share in Japan grows to over 20 percent. This great success is partly due to the introduction of the FE1 and FE2 model series in October 1978. Now, in addition to the narrow vehicles, there is also a wide version with a payload of two and three tonnes. A little later, a comfortable power steering system was added to the equipment list.

VARIETY OF VARIANTS OF THE CANTER INCREASES

The T200 series receives extensive changes to all important components. The redesigned front of the cab is recognisable at first glance. Even then, the compact light truck can serve with a certain diversity of variants, namely there is the T200 with different wheelbases and platform heights and now also as a variant with a three-tonne payload.

CANTER GETS MORE POWER

A completely new model series, the T90 series, is coming onto the market. Not only has the look changed, but something has also changed under the cab: all models are now equipped with dynamic and powerful engines (75 hp diesel or 90 and 95 hp petrol). As a result, the Canter achieves the best acceleration and speed values in its class. Which obviously goes down very well with buyers – the market share in Japan doubles by leaps and bounds the following year.

MITSUBISHI UNVEILS FIRST LIGHT TRUCK

With the T720, Mitsubishi Nippon Heavy Industries Ltd. presents its first light truck. The compact front-wheel drive two-tonner is considered the original version of the FUSO Canter. It is available in several body variants and with both a 90 hp petrol engine and a 68 hp diesel. It gets its name, Canter is the term for light gallop, to associate the character of the vehicle with the agility and endurance of a horse.